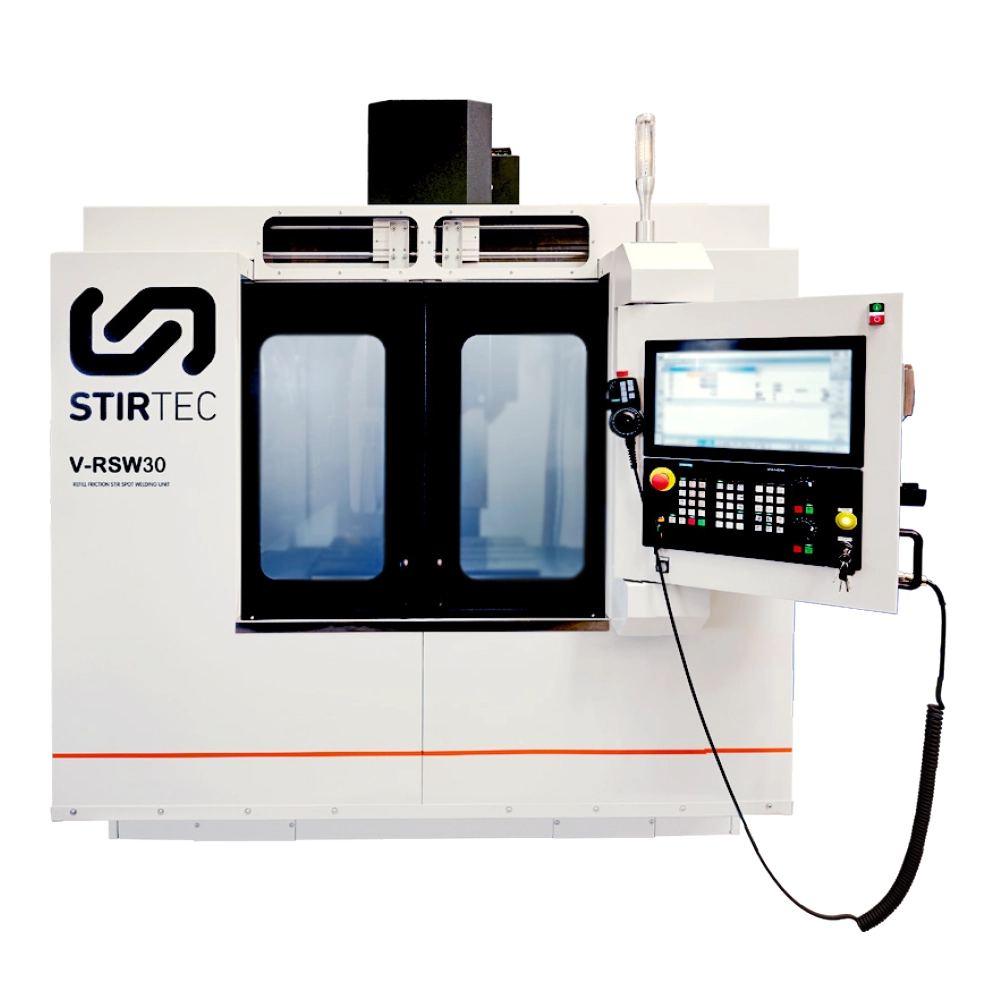

RFSSW | Refill Friction Stir Spot Welding SERIES

Spot welding machinery for exceptional electric transmissionWith the demanding requirements on most efficient battery systems and charging infrastructure, Stirtec presents the machine type V-RSW30 for industrial use of the innovative welding technique Refill Friction Stir Spot Welding (RFSSW). Following the advantages, the welding process is executed force-controlled under the performance of the special developed spindle system. No additional materials are required to execute the welding spot, leading to highest joint strength with exceptional mechanical and electrical properties. High currents for busbars and connector, for example, can easily be transferred to dissimilar components. The influence of coatings and remaining isolation has no impact on the quality, eliminating the need for complex and expensive cleaning processes before welding. To support electrical transmission, the welded spot area finishes with a smooth surface refilling the entrance position of the tool.

V-RSW30For part dimensions up to L 500 x W 500mm (option for open access without housing)

Force and position control system

Special developed RFSSW spindle for industrial use

Exceptional mechanical and electrical properties

Overview on the Refill Friction Stir Spot Welding series

V-RSW30

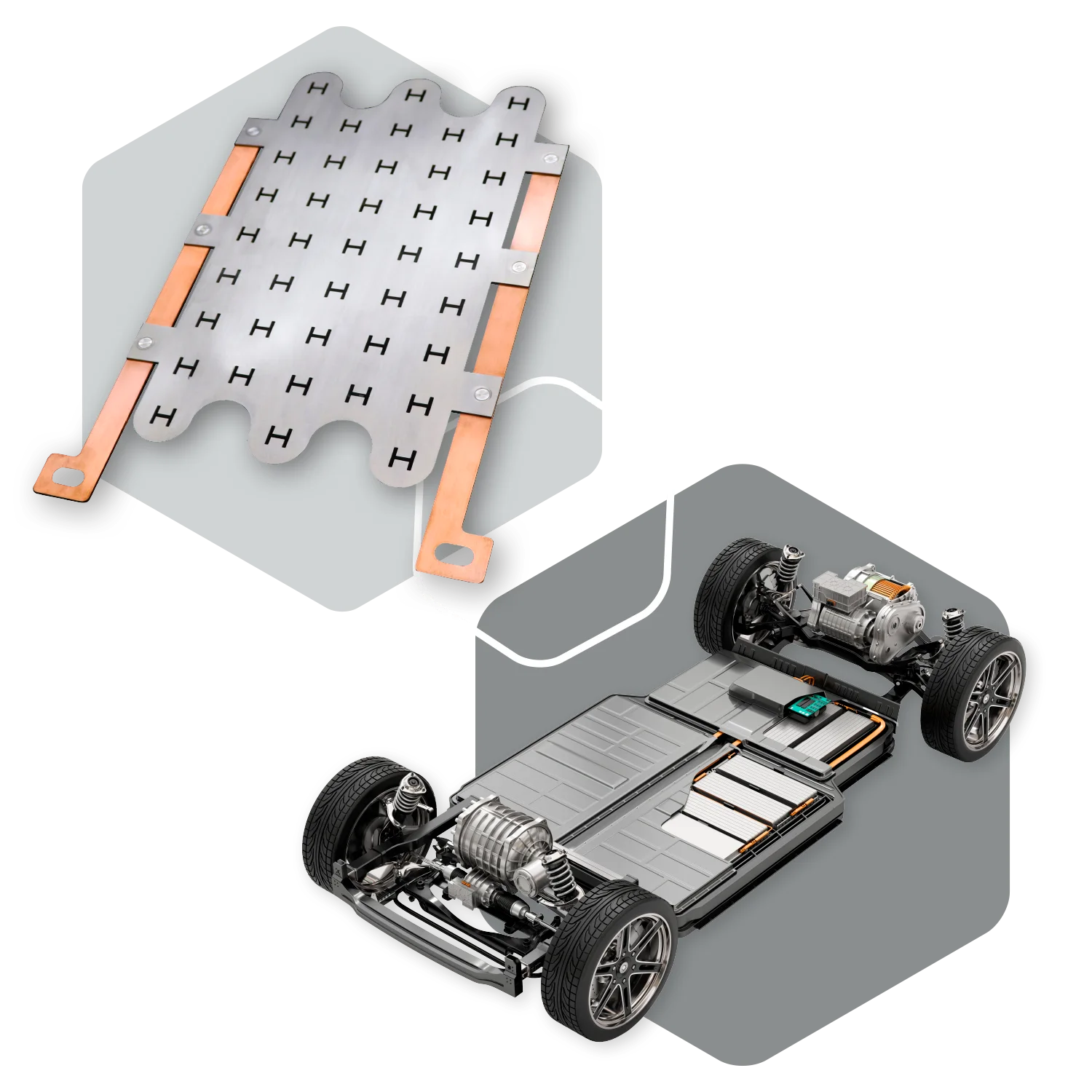

- Application for spot-welding: flat busbars, electric connectors and aviation/aerospace structural parts

- RFSSW machinery for dissimilar joints (aluminum-copper) and all aluminum alloys with exceptional efficiency

Download DatasheetV-RSW30

The Stirtec V-RSW30 series provides the innovative spot-welding technology RFSSW for a wide range of serial applications in industrial use. Due to the special developed spindle system, similar-dissimilar materials are joined together with outstanding mechanical and electrical properties. The welding process is performed position/force controlled or in a combination of both control modes. The machine is capable of spot-welding solid pure aluminum to copper or electrical wiring to busbars or electric panels with a large conductor cross-section. The two variants of the refill process can be realized: pin and sleeve plunge. Including the inline process monitoring software STIRlytics®, process forces and real-life data collecting are combined into a quality report for 100% traceability.

Machine characteristics of Stirtec V-RSW30

- application size up to L 300mm x W 300mm

- use of Sinumerik 840D s/ machine control system

- STIRlytics process software for 100% traceability

- FSW force measuring system in X-, Y- and Z-direction

- high repeatability and easy spot positioning

- suitable for all aluminum alloys and copper applications

- special-developed RFSSW spindle

- short cycle timing under the use of no consumables for connecting

- full protection and CE-conformity

For more information, please get in contact

Applications for the RFSSW Series

Charging Systems

RFSSW (Refill Friction Stir Spot Welding) and FSSW (Friction Stir Spot Welding) are used, among other applications, for aluminum-copper hybrid connections in electromobility. This is especially relevant when a large cross-sectional area of the joint is needed for low-resistance power transmission.

Find out more about Charging Systems

FOR FSW PROTOTYPE PRODUCTION AND MACHINERY

Your contact person: Dominik Kaineder

Are you interested in determining the feasibility of a new concept using Friction Stir Welding? Or do you require assistance in choosing the most-sufficient system for serial production for your application?

Please contact us directly - we'll gladly provide guidance and support.

dominik.kaineder@stirtec.at

+43 676 30 93 922